4 Weeks. I had 4 Weeks to Build a Start-Up from scratch.

This included:

- Thinking of an Idea

- Finding a Target Audience

- Building a Product – R&D

- Assembling a Team

- Addressing Issues and Failures

- Marketing

But now those four weeks are up, and I would like to introduce LightVest.

Start-Up Name: LightVest

Slogan: Improving Cycling Confidence at Night

Official Site: LightVest.io

LightVest – “An LED Turn Signal Bike Safety Vest”

LightVest is an open-source Bike Safety Vest designed to be a wearable technology. The product is a Bike Suit designed to increase a cyclist’s visibility, especially during the night. As well as improving cyclist’s communication with other motorists and pedestrians.

Features

- A lightweight Weatherproof LED Vest (with IP67 Rated LEDs)

- Turn Signal’s – Fully programmable RGB 5050 LEDs

- Wireless remote to control the lights (with four fully customizable buttons)

- A Bike mount to attach to your Smart Remote to your Bike Handle

- ON/OFF Switch Button

- Go Hand’s Free with an In-built accelerometer – control Turn signals from your bike handle.

- Smart Mode – Send Data and track your Journey by Phone

Since it’s open-source using Bluetooth technology, you can even track your journey through your phone – or use this data for more insights.

This Article would detail how the process of building a Start-Up (LightVest), and some takeaways from a business perspective.

Or alternatively, visit how Lightvest Bike Suit was built / Tutorial

Ground Rules:

It’s important to lay some ground rules, so here they are:

- Attempt to Launch a Product in 4 weeks

- $500 Investment

- Can work on this Project (After 7 pm / Work) Excluding Weekends

So doing the maths our new business hours is 7 – till late.

Building a Start-Up is an interesting thing. But what exactly is a Start-Up:

“A start-up is a young company founded by one or more entrepreneurs to develop a unique product or service and bring it to market. By its nature, the typical start-up tends to be a shoestring operation, with initial funding from the founders or their friends and families.” – Investopedia

Funding:

Equipped with $500, and at the early peak of the Dunning Kruger Graph. This is my attempt at launching a Start-Up. Let’s start this.

Finding a Product – The Idea:

When creating a product, I like to think that we’re creating a solution to a problem. And even better is developing a solution to a problem that even your customers aren’t aware of is a problem.

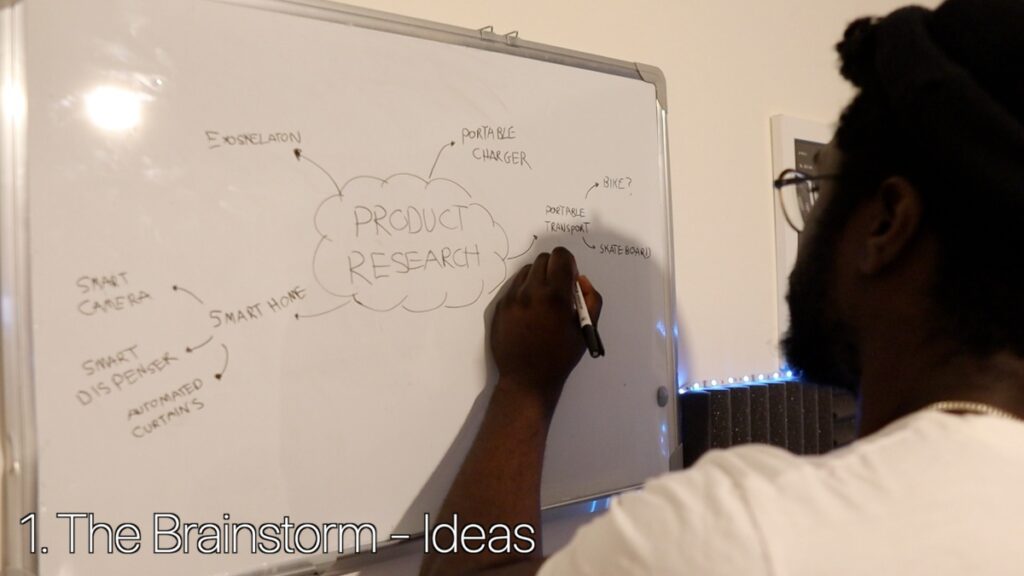

When it comes to generating ideas, there isn’t any rule to creativity. The process I’m going to follow is a mixture of generating ideas through a brainstorming session of problems and checking the demand on that key term based on its analytics.

- To identify/shortlist an idea, the three factors I’ll focus on:

- Relative low barrier of entry (only got $500)

- High Demand on Audience

- Room to innovate on Idea

- The same theory is what was used to generate the Idea of an LED Suit.

- But coming to that Idea wasn’t easy in fact, after three days of no good ideas. The thought popped up after staring at my LED strip on my wall. A wearable LED Suit.

- Weirdly enough, some ideas come in when you’re not thinking about them. (The Eureka Moment)

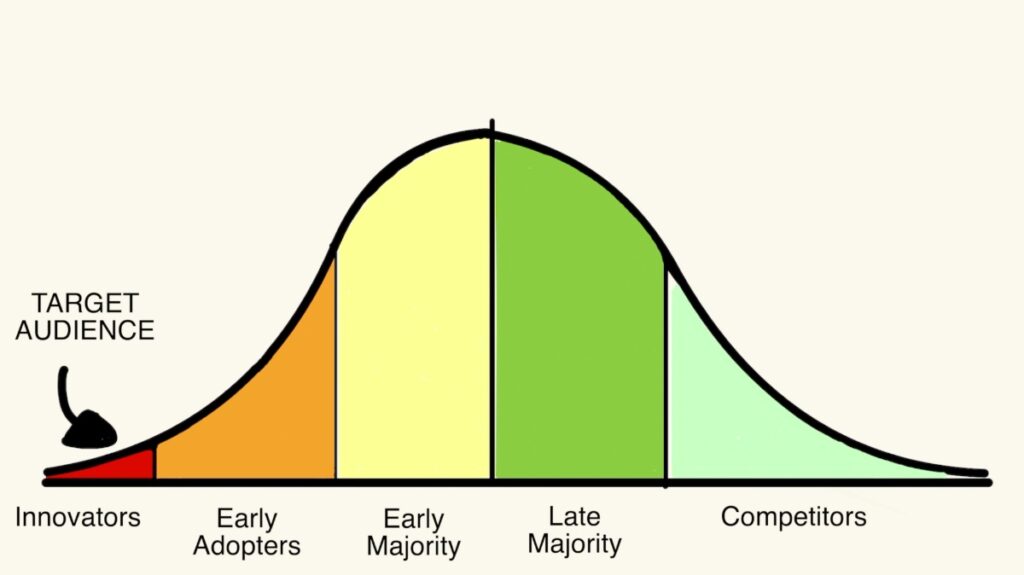

The Target Audience:

Now that I have the Wearable LED suit idea, the Target Audience is essential as they’re the customers we’re providing a solution for this issue.

An LED Suit can fall under a lot of categories, but after a bit more research into existing LED wearables, the Bike Industry was the one that stood out.

Creating the MVP – How it Works:

Week 2 – Current update: now we’ve proved the proof of concept. It’s now time to spend our investment.

Now to prove that creating an LED wearables is something possible. I would need to create an MVP—a Minimum viable product.

“A minimum viable product (MVP) is a version of a product with just enough features to be usable by early customers who can then provide feedback for future product development.” – Wiki

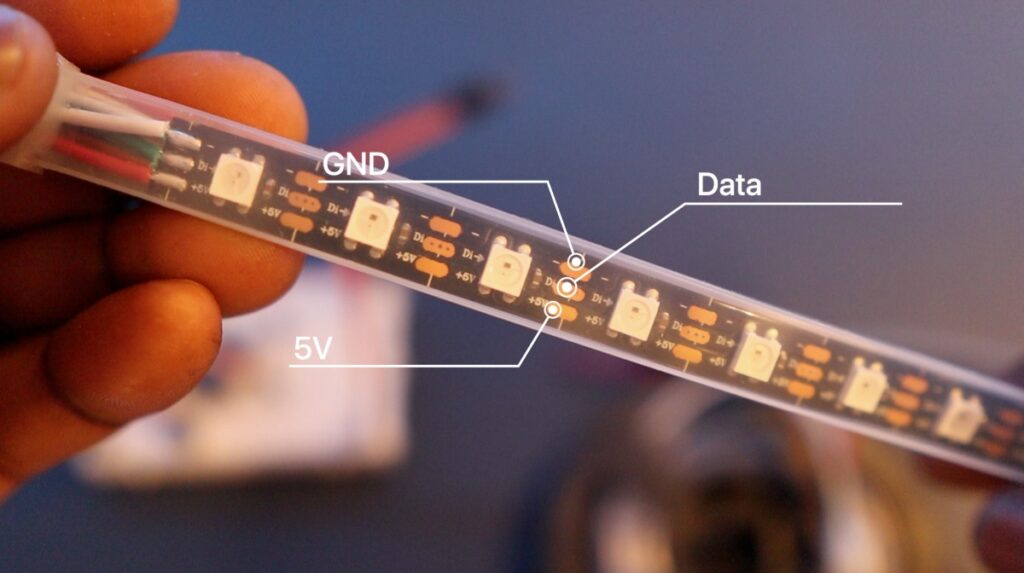

- Ideally, we have a LED Strip powered by an Arduino – these have RGB Light that is controllable to any RGB hue and can be cut to any size.

- We can power LighVest using a small microprocessor. In this case, we’re using an Arduino Nano

- Finally, we can power the LEDs using a small battery.

- The idea here is that if we have a wearable strip, we can use the series of 5050 LEDs to indicate whether we’re moving left or right when riding a bike.

- With that sorted, we can even make a portable remote for the LED strip that can control the light from a distance.

- In addition, we need innovation to add more functionality than the competitors: If we add an accelerometer to the Bike remote rather than the LED wearable to reduce the number of electronics. We can then use the handle as the indicator, meaning we can signal left and right without lifting a finger or even being aware of the wearable Led suit.

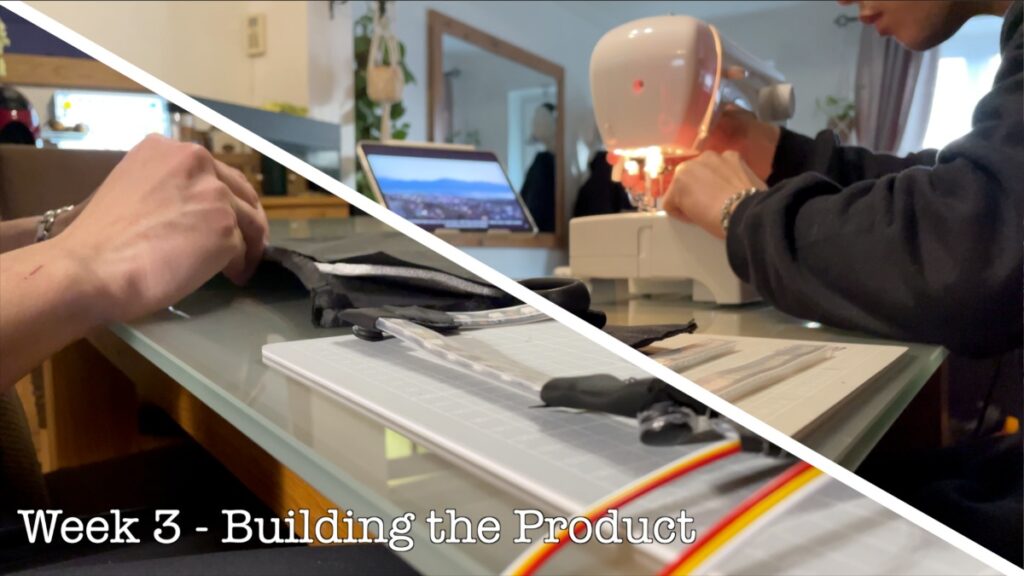

Building the Team

To scale this Start-Up Idea, building a team of experts is going to essential. Given that this product is wearable technology/clothing and would need some help with Fashion.

One thing about the existing competitors is their design. I believe for this to be more of a practical solution; it needs to be fashionable. And this is where I call an old-time friend.

LightVest Fashion/Design Factors:

- Discrete

- Fashionable

- Practical

A few sketches of the original design concepts were drawn, with the above points in mind. Finally settling with a more straightforward and ‘less flashy‘ design. The LightVest consists of:

- The diamond-like indicator at the back

- Front Light Strips on Shoulders

The below table explains what each LED part does

| LED Strip | Colour | Function |

| Diamond Strip – Half | Yellow | Turn Left or Right |

| Diamon Strip Red | Red | Abrupt Brake Lights |

| Front Shoulder trip | Yellow | Turn Left or Right |

| All LED on Blinking | Yellow | Hazard / Emergency |

If you want more details, here’s the full tutorial on creating a wearable LED Bike suit for more details on building your own.

Now you’re back. Okay, let’s continue!

So a summary: We’ve now identified our Idea, Target audience and have implemented a solution to address cycling during the night. We’ve now created an MVP and implemented our very first prototype.

Since the LED Bike remote is in its alpha test stages, there is still room for improvements. The next following steps are to design a PCB to shrink the size of the components. After all, we still have a breadboard within the remote!

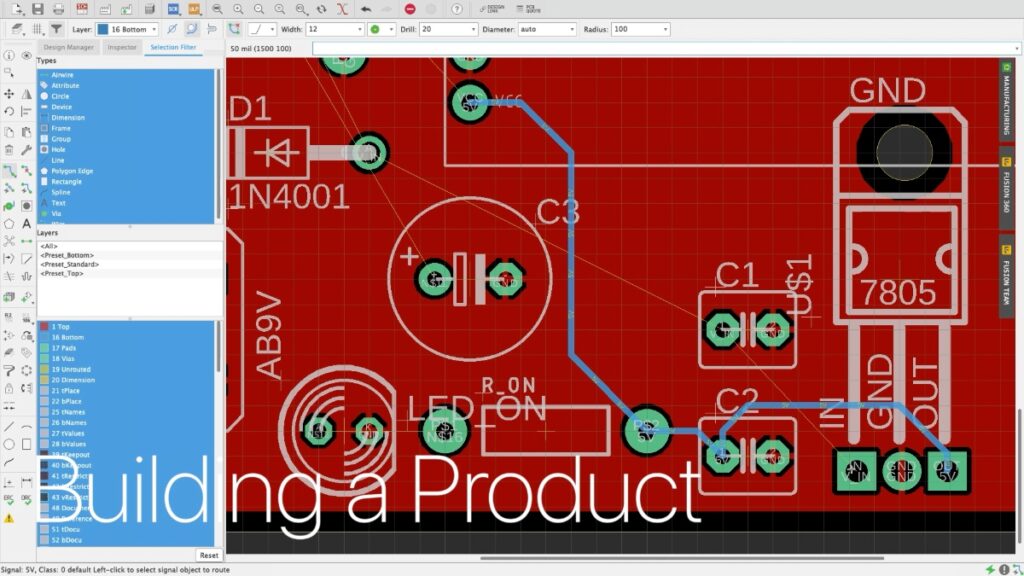

PCB Creation

Creating a PCB helps reduce the development board’s footprint and keeps everything in place. As the Breadboard is more for prototyping and would not be as practical in the real world. You can find the schematics in the download section.

A PCB was designed for both the LED Bike Suit and the LightVest remote. “Since it would take around 7 days for the PCB to be delivered, we’ll put this in the background and just hope it works the first time round!” – Famous Last words

One small issue. Scalability

The advantages of a software-based start-up are that resource-related issues are limited to the amount your server can handle, and theoretically, a user can purchase a software game without much assembly and shipping investment into each purchase. However, since this product is a hardware-related project, we would need to design the parts, source materials, and assemble them physically (somehow). This is where a scalability issue comes into the picture.

Scalability – whether it be in a financial context or within a context of business strategy, describes a company’s ability to grow without being hampered by its structure or available resources when faced with increased production

There are two main options.

- Option 1: We can create and assemble these in-house, but with such a small team that won’t be scalable.

- Option 2: We can partner up with a Factory to build the product. However, the initial costs a particular vendor asked was far above our initial investment of $500.

However, both the former leads to a scalability issue, while the latter would put LightVest deplete all of LightVest funds. We’ll need to address this issue.

Marketing:

Week 3 – Current Update: Prototype and PCB, schematics created awaiting delivery.

Marketing was the most interesting part of this. As of now, we’ll need to officially put a brand name to it. (And yes I know), I actually put some time into creating an Ad campaign, making a Website, and even preparing to sell it like an actual product.

Now thinking of a name can be fun and quite challenging at the same time as ideally, you want a word to represent your brand. Or the solution you’re providing.

Thanks to you guys on Instagram (follow @smartbuilds.io). I put out a post on Instagram for Start-Up Ideas and got quite a good amount of Ideas. We’ve shortlisted those, and the Winner was LightVest, so shout out to i.am.jeanpierre (Instagram).

- LightVest was a good name and was quite lucky as the domain is great for SEO, although a competitive term. Anyone who’s searching for the name LightVest is more likely to stumble on this site as It very much an exact keyword. (Using the .io extension was just so it could sound more like a start-up.

With that done, a whole site was created: visit lightvest.io

Manufacturing Costs – Cost of Product

The breakdown of parts is based on the retail price and not on the wholesale.

Note: The price can be driven down significantly with dedicated electronic parts and wholesale prices.

This is a ball part estimate and doesn’t include labor hours.

| Parts | Retailer |

| 2 x Arduino Nano | |

| MPU6050 (Accelerometer) | |

| LED Strip (WS2812B) | |

| Jumper Wires | |

| 2 x Bluetooth HC-05 | |

| 2 x Slider Switch | |

| Push Button | |

| Capacitors | |

| Breadboard |

The cost to build this product is about ~$49.99. However, this is just the cost alone for standard DIY Components. And the price could be theoretically be driven down by purchasing items on wholesale and using more efficient parts, e.g, ATTiny Microcontroller. Rather than using an Arduino, which costs $5 – $20. As a result, we could drop the price down significantly.

But at the end of the day, scalability is still the biggest issue.

Hurdles

How can you make this scalable?

Things are starting to take on an upward trajectory. We got the MVP, we’re waiting on making a PCB version. We still got $200 to spend. However, the scalability issue is still a major problem to address.

With manufacturing cost exceeding the $500 budget, pivoting seems like a good option.

Pivoting

Pivoting – A start-up pivot occurs when a company shifts its business strategy to accommodate changes in its industry, customer preferences, or any other factor that impacts its bottom line. It’s essentially the process of a start-up translating direct or indirect feedback into a change in its business model.

The Ikea Business Model:

Ikea’s business model works on providing the customers with the whole unassembled package, which means they could have lower prices as they don’t spend much on the assembly process. An unassembled box works in the long run as you can pack more volume per shipping.

- Fully Customizable

- Since it’s open-source, LightVest builds a platform to iron out potential issues and for others to build even better solutions.

- Meaning you can add more to it, e.g., GPS tracker. All parts, codes, PCB, and resources can be found on LightVest GitHub Repo.

- All parts, codes, PCB, and resources can be found on LightVest GitHub Repo

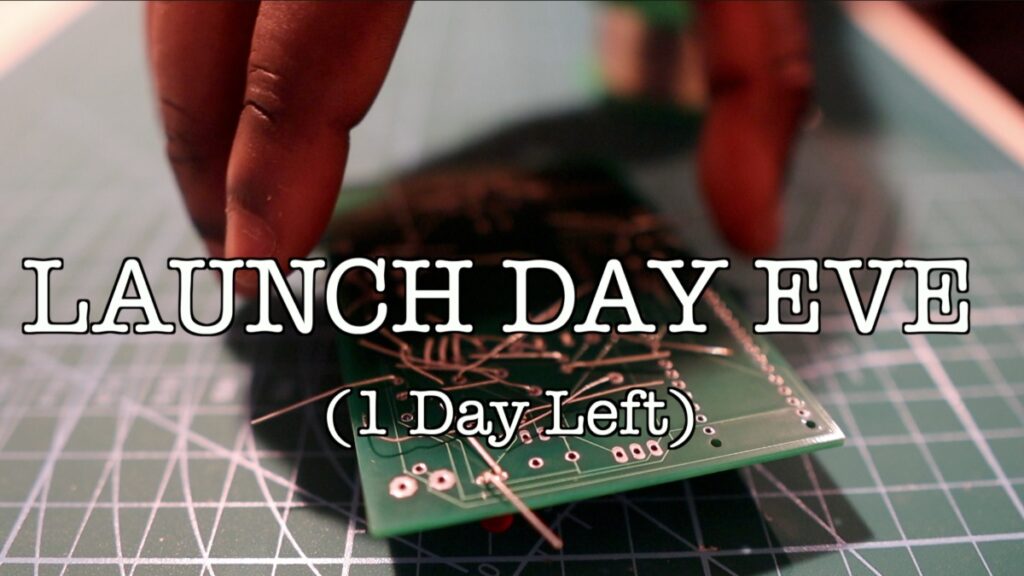

1 Day before Launch:

And that’s it, we’ve pretty much launched!

LightVest is open source and free, designed to be improved and developed on. So After four weeks from The Idea to Launch, here we are.

You may be wondering did you make money at Launch. So it’s been three days; it’s hard to tell, but this concludes the Launch of the LightVest product as part of the 4-week start-up.

Conclusion – Takeaway

- It’s good to have a good idea of what’s your Budget/Investment before can get you to spend.

If an idea doesn’t work. Don’t give up yet – see if you can Pivot - How do you find a good idea? Make new connections between two remote concepts – Isaac Asimov on Creativity

- Immerse yourself; you’re more than likely to have a hobby/passion for something that’s has a problem. Most people may brush the problem off as a minor inconvenience. How about drilling down on that problem to see if there’s enough of a demand to solve that issue by providing a solution.